Our expertise

FusiA 3D Metal Printing Inc. implements comprehensive expertise in metal additive manufacturing, supported by controlled processes, certified quality and a strong dynamic of innovation.

Processes

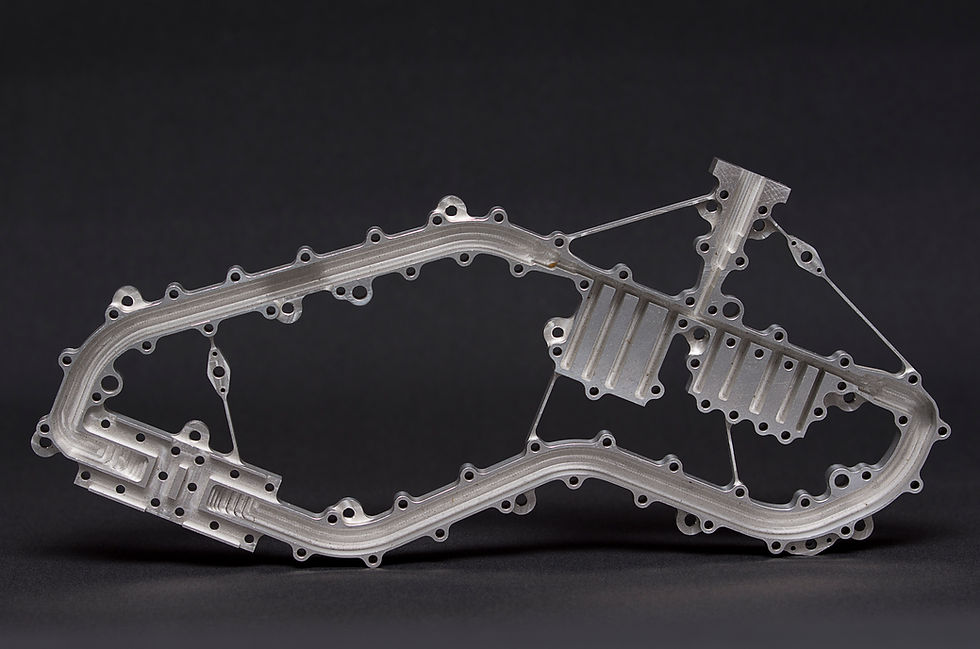

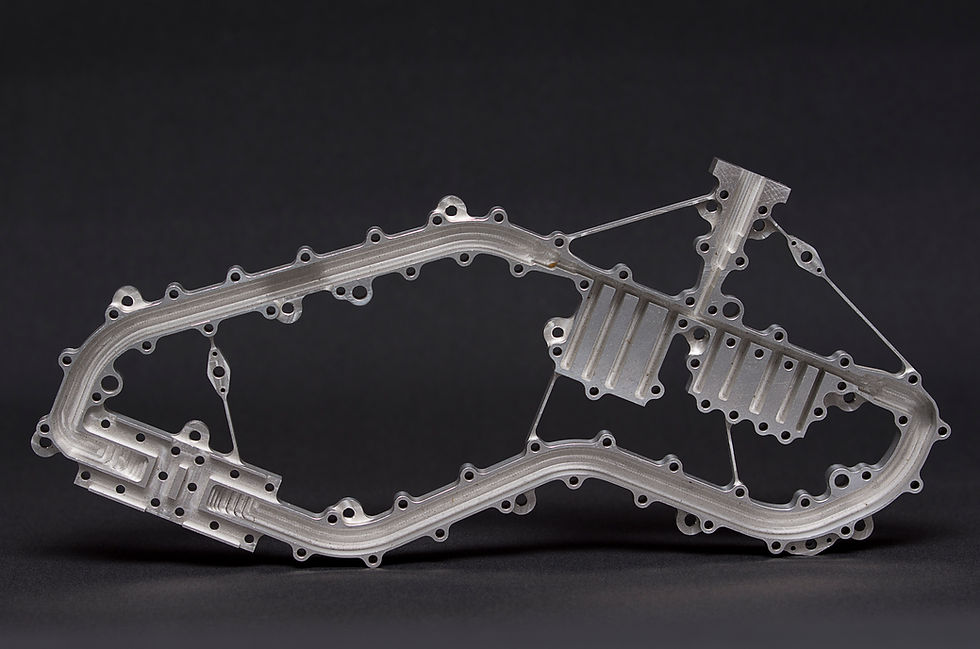

Expertise in L-PBF (Laser Powder Bed Fusion), covering design through post-processing

Production

Manufacturing of prototypes, tooling, pre-production runs and industrial parts

Aeronautics, space, defense and industry

DESIGN - 3D PRINTING - MACHINING - POST-PROCESSING - QUALITY CONTROL

DESIGN

We support our clients from the design phase to guarantee the performance and manufacturability of the parts.

-

Identifying relevant parts for additive manufacturing

-

Support and training in 3D metal design

-

Redesign and optimization of existing designs based on plans

3D PRINTING

Our production capabilities rely on state-of-the-art equipment ensuring precise, repeatable manufacturing that meets industrial requirements.

-

2 EOS M 290 printers dedicated to the L-PBF process

-

Wide selection of metallic materials (aluminum, titanium, stainless steel, Inconel, etc.)

-

Print volume: 250 × 250 × 300 mm (10 × 10 × 12 in)

MACHINING

Thanks to our sister company HRT Industries, we carry out in-house the machining operations necessary for the finishing and sizing of parts produced by additive manufacturing.

-

In-house machining for complete process control

-

Cutting the tabletop and removing the supports

-

Machining according to customer drawings and requirements

-

Machine park including 5-axis and 3-axis CNC machines, CNC lathes, conventional milling machines and welding equipment

POST-PROCESSING

FusiA provides all the necessary operations for the finishing and conformity of metal parts, combining internal processes and specialized outsourced treatments.

-

Surface finish improvement

-

Sandblasting / microblasting

-

Tribofinishing

-

Anodizing (outsourced)

-

Heat treatments (outsourced)

CONTROL

Our measurement methods guarantee dimensional conformity and traceability of manufactured parts, from the printing output to final validation.

-

Hexagon 8520 7-axis articulated arm

-

Measurement envelope: 2.5 m (6.6 ft)

-

Probing: tolerance ±0.029 mm (0.0011'')

-

Scanning tolerance: ±0.045 mm (0.0018")

-

-

Inspection reports according to 2D plan

-

Analysis of deformations after printing

-

Outsourced controls: radiography, tomography, etc.