Why Choose Metal Additive Manufacturing? Advantages, Limitations, and Industrial Applications

- Nov 20, 2025

- 2 min read

Metal additive manufacturing is rapidly establishing itself as a key solution for industries seeking performance, agility, and cost efficiency. At FusiA Group, we invested early in this technology because it delivers tangible, often underestimated benefits that are essential to staying competitive.

Lighter parts, no compromise

Additive manufacturing does not start from a solid block like traditional machining. Geometry is optimized, unnecessary material is removed, and lightweight internal structures are generated.The result: lighter parts without sacrificing strength—an essential advantage in aerospace, space, and any sector where every gram matters.

Unmatched design freedom

The technology enables the production of complex geometries that are impossible or too costly to achieve through machining.From rapid prototyping to functional parts, limited series, or full-scale production, metal AM provides a level of flexibility that fundamentally changes the relationship between design and manufacturing.

Significant waste reduction

Unlike subtractive processes, additive manufacturing uses only the material required to build the part. The remainder is reused after sieving.This dramatically reduces waste and optimizes material costs—a decisive advantage for specialty alloys like Inconel, Ti-6Al-4V, or 17-4PH.

Easy access to a wide range of materials

No need to stock bulky raw billets or manage complex supply chains.Metal AM makes it possible to work quickly with various materials, with consistent powder quality and mechanical performance comparable to conventional processes.

Performance suited to the most demanding industries

Mechanical properties delivered by metal AM are proven and validated in critical environments.That’s why aerospace, space, defense, industrial, and energy sectors now rely on metal additive manufacturing for production-grade components.

The limitations to understand to leverage the process fully

A specific design approach

Additive manufacturing requires a different mindset: orientation, excess thickness, thermal management, supports, post-processing…It’s a discipline of its own.

At FusiA Impression 3D Métal Inc., our team supports each customer from the design phase to ensure optimal results and avoid costly errors.

Support removal and post-processing

Most parts require support structures that must be removed afterward. This step demands precision and expertise. Thanks to HRT Industries, our integrated machining unit, we internalize all post-processing operations. This shortens lead times, ensures consistent quality, and simplifies the production chain for our customers.

Why choose FusiA Group?

FusiA combines two key capabilities: metal additive manufacturing and high-precision machining.This dual expertise allows us to:

produce complex parts with short lead times,

control the entire workflow from design to post-processing,

provide full technical support,

guarantee consistent quality for critical applications,

remain competitive on total cost thanks to material optimization and internal processes.

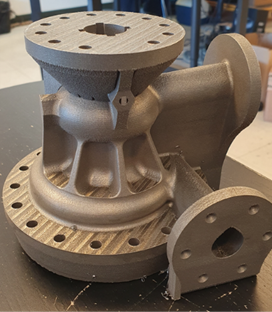

Examples of metal 3D-printed parts produced by FusiA Group:

Article written by FusiA Group